Industrial ovens are important equipment for many manufacturing processes in California. They are used for purposes like baking and curing. But just like every other appliance, your industrial oven can also get on the fritz if you don’t properly take care of it. This can happen in no time without a professional’s touch, as regular maintenance is key.

To keep your commercial oven functioning properly and for a long time, you need the touch of a professional technician. That’s where the importance of professional technicians step in. With them, expect your industrial oven to last longer.

In this blog, we will show you the role of professional technicians in your oven repair and in sustaining the appliance.

Let’s unveil!

The Role of a Professional Technician in Industrial Oven Repair

Industrial ovens are closed spaces that use heat sources to reach certain temperatures for industrial baking purposes. They are somewhat different from your regular kitchen oven. These types of ovens can bake more amount of materials and can sustain even higher temperatures.

Over here in California, we are known for manufacturing. This makes industrial ovens even more rampant and shows its importance. Different businesses and industries like food processing, aerospace, automotive, and electronics need to use these ovens a lot. They need them for baking, drying, curing, and heat treating.

The effectiveness of these businesses is dependent on how effective their ovens are. So, for companies to keep the quality of their product or services intact, they need to keep their oven working in its best condition.

The Critical Role of Industrial Ovens in Manufacturing and Production

Let me say this again: the success of your manufacturing processes depends on how accurate and trustworthy your industrial oven is. These ovens are built to reach and hold certain temperatures very accurately. This helps to keep the quality of your product consistent.

A good industrial oven ensures that every spot of the oven gets an equal amount of heat as every other part. There are no hotter spots. This is key to manufacturers that rely on very strict temperature controls. For some businesses, a little temperature change can affect the entire quality of their products.

Why Regular Maintenance and Repair is Non-Negotiable for Safety and Efficiency

Any company that makes it a habit to always take care of their oven is sure of both safety and effectiveness. Regular upkeep, like checks, cleaning, and changing parts, helps avert breakdowns and expensive downtime.

By taking a proactive approach to maintenance, you can quickly spot potential problems early enough before they escalate. It’s also very important to ensure a safe environment for your staff who work with and near the industrial oven.

If you stick to a preventative maintenance schedule and deal with repairs asap, you lower the risk of hazards and create a safe workplace. That’s not all, it also helps your oven run better and cuts costs over time.

Identifying Common Issues in Industrial Ovens

Industrial ovens are usually strong, especially when you get a renowned brand, but they can wear down over time. This is because they run for long hours and operate under extremely hot temperatures.

Common industrial oven problems are broken heating elements, bad thermostats, and issues with ignition systems, burners, or airflow. The first step in making repairs is identifying the root cause.

Recognizing Signs of Malfunction in Gas and Electric Industrial Ovens

Different types of industrial ovens can show specific. For example, gas ovens might have issues like unsteady flames, delays in ignition, or strange noises from the burner. A strong smell of gas could also mean there is a leak, and you should deal with that right away.

Electric ovens also have their problems. They may heat unevenly. They can also cause circuit breakers to trip, or give off a burning smell, which can be a result of faulty heating.

But here’s something else you should know. No matter the type of event you have, if you experience strange noises, changes in temperature, or visible damage, you should involve the professionals asap.

Preventative Measures to Avoid Downtime and Ensure Continuous Operation

Preventative maintenance is by far a better option than having to deal with sudden breakdowns. It helps lower the chances of dealing with costly repairs.

It’s important to check and regularly clean both the outside and the inside of your oven. Make sure you clean the heating parts while you ensure your seals are not damaged. Also, by lubricating moving parts, you can reduce the rate of wear and tear.

Setting up industrial oven maintenance services with a trained technician is an important and smart way to fix small problems before they escalate to something big.

The Expertise of Professional Technicians in Oven Repairs

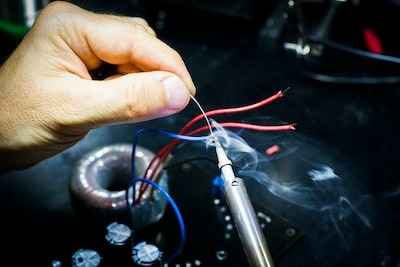

When your industrial oven breaks, it’s best not to attempt fixing it if you have zero knowledge and skill in DIY industrial oven repair. Trying to fix complex industrial ovens by yourself can be risky and can lead to hazards.

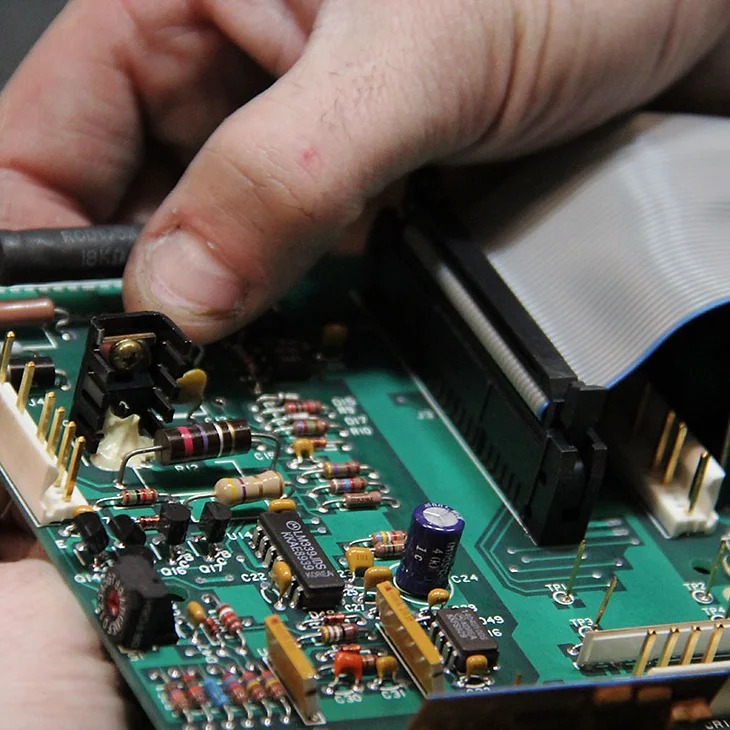

Professional technicians have a lot of experience and knowledge of different sorts of industrial ovens, how they work, and their parts. They have the right tools and experience to safely make commercial oven repairs.

Qualifications and Skills: What Makes a Technician Stand Out?

Choosing the right technician for your industrial oven repair is very important. You should think about their qualifications, skills, and experience before you decide. Look for technicians who have many years of experience with industrial ovens. It’s best if they have worked with ovens like yours, which fit your industry.

Certifications from well-known organizations show that a technician is dedicated to keeping up high standards. It also means they are aware of the latest practices in the industry. You may want to ask about their experience with common oven problems and how to troubleshoot them.

A good understanding of safety rules is also essential for any technician. This is especially true for those who work with gas-fired or electrical ovens. By choosing a knowledgeable and experienced technician, you can be sure your oven is in good hands.

A Word From Us

Professional technicians play an important role in fixing industrial ovens over here in California. With a professional technician, your industrial oven is kept safe, efficient, and in good health. Quick repairs and regular maintenance are key to avoiding downtime and extending the life of industrial ovens.

Over here in California, STAR Appliance is your go-to option for your industrial oven. With our wealth of experience, we have to know-how and the expertise to address any industrial oven repair. If you need expert technicians in California, contact us today. Your oven is our top priority

Frequently Asked Questions

What Are the First Signs That an Industrial Oven Needs Repair?

The first signs you might notice are heating that isn’t steady, changes in temperature, strange sounds, and a smell like something burning. This could be due to a broken heating element or problems with the oven’s control system. It’s best to get a professional to help with troubleshooting.

How Often Should Industrial Ovens Undergo Professional Maintenance?

To keep your industrial ovens running their best, it’s important to have them checked and serviced by a professional at least once a year. If you use the oven often or have a specific type, you might need to maintain it even more often.

Can Regular Maintenance Extend the Life of an Industrial Oven?

Regular maintenance is very important for an industrial oven. It can help the oven last longer. When you fix small problems before they get worse, you avoid big breakdowns. This way, the oven runs safely and strongly for a longer time.

Are There Any DIY Repairs for Minor Industrial Oven Issues?

Simple jobs like cleaning and changing air filters can be done at home. However, for more complex issues with an industrial oven, like troubleshooting and replacing spare parts, it’s better to let qualified technicians handle it.

How Do I Choose the Right Technician for My Industrial Oven Repair in California?

- Look for technicians who have valid certifications.

- Check how many years of experience they have.

- Read their positive customer reviews.

- Ask them about their work with your oven type.

- Find out if they know the safety rules in California.